Motorized One-Piece Flanged Ball Valve (DN15-DN350) - Unibody Zero Leakage | DELCO

The DELCO Motorized One-Piece Ball Valve is a compact automation solution featuring a rigid unibody design. Powered by our high-performance Motorized Electric Actuator (On-Off or Modulating), it eliminates external body leak paths common in multi-piece valves. Available in DN15–DN350 with WCB or Stainless Steel bodies, this reduced-bore valve is ideal for HVAC, water treatment, and steam lines requiring strictly ANSI/DIN/JIS compliant flanged connections.

Size Range: DN15-DN350

Size Range: DN15-DN350

Material: WCB, Stainless Steel etc.

Material: WCB, Stainless Steel etc.

Connection Standard:GB / ANS / JIS / DIN

Connection Standard:GB / ANS / JIS / DIN

Features

Engineered for leak-free performance and cost-efficiency, combining a solid unibody structure with reliable motorized actuation

✅Unibody Design for Zero External Leakage

The valve body is cast as a single solid unit without bolted joints or body seals. This "One-Piece" construction removes the potential leak paths found in 2-piece or 3-piece valves, offering superior safety for critical utility lines.

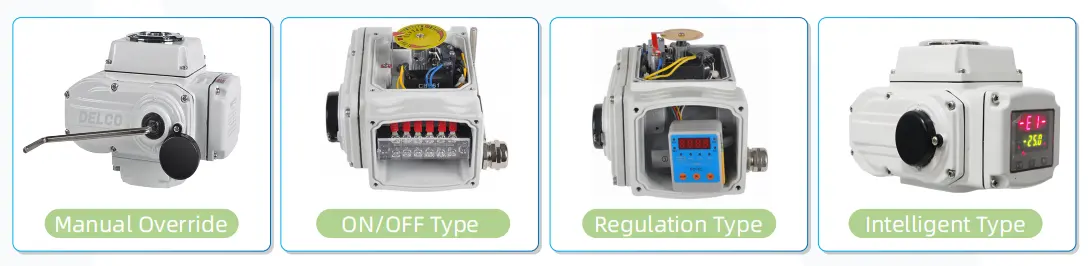

✅Reliable Motorized Actuation

Integrated with the DELCO Electric Actuator, featuring a high-torque motor and hardened gear train. It supports rapid On/Off operation or precise 4-20mA positioning, complete with IP67 weatherproofing and a visual indicator for clear status monitoring.

✅Economical Reduced Port Configuration

The valve utilizes a reduced bore (venturi) design. This allows for a lighter, more compact valve body and lower operating torque requirements, significantly reducing both the valve cost and the actuator size without compromising essential flow rates for water and steam.

✅Durable WCB/Stainless Steel Materials

Constructed from heavy-duty Cast Steel (WCB) for high-pressure durability or Stainless Steel (304/316) for chemical resistance. Standard features include a blowout-proof stem and anti-static design for industrial safety.

✅Universal Flange Integration

Designed for global versatility, the integral flanges are machined to meet ANSI 150/300, DIN PN16/40, and JIS 10K/20K standards, ensuring seamless retrofitting into existing international piping systems.

Photo

Photo

Video

Video

Industry Applications

-

Oil & Gas

Electric actuators enable reliable remote shutoff and precise positioning for pipeline and process valves. Optional on/off or modulating control with feedback signals. -

Chemical & Petrochemical

Stable electric actuation for corrosive-duty applications. Supports modulating control and position feedback to match PLC/DCS requirements. -

Power Generation

Designed for power plants where dependable actuation and accurate positioning are required on steam/water auxiliary lines and balance-of-plant systems. -

Food & Pharmaceutical

Electric actuation for sanitary valve automation. Clean operation with configurable control and feedback—confirm enclosure and material requirements by application. -

Water & Wastewater

Ideal for treatment plants and pump stations—remote on/off or modulating control, position indication/feedback, and continuous field operation. -

HVAC & District Heating

Accurate valve actuation for energy-efficient HVAC networks. Smooth flow regulation with modulating control options.

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application