Home / Product / Globe Control Valve /

Home / Product / Globe Control Valve /

Electric Globe Control Valve (DN15-DN600) - Single Seat & Sleeve Type | DELCO

The DELCO Electric Globe Control Valve Series is a high-performance automated regulating valve designed for the precise control of flow, pressure, and temperature in process pipelines. It integrates the advanced 3810L Series Electronic Linear Actuator with a balanced Single Seat or Sleeve (Cage) valve body. Available in DN15–DN600 with WCB/Stainless Steel bodies, this valve offers superior stability, high pressure-drop capability, and low-noise operation, compliant with ANSI/DIN/JIS/GB standards.

Size Range: DN15-DN600

Size Range: DN15-DN600

Material: WCB,Stainless Steel etc.

Material: WCB,Stainless Steel etc.

Connection Standard: GB/ANSI/JIS/DIN

Connection Standard: GB/ANSI/JIS/DIN

Features

Engineered for industrial automation, this valve combines intelligent 4-20mA control with a robust balanced trim design to handle high-pressure differentials:

✅Integrated Electronic Actuation (3810L Series)

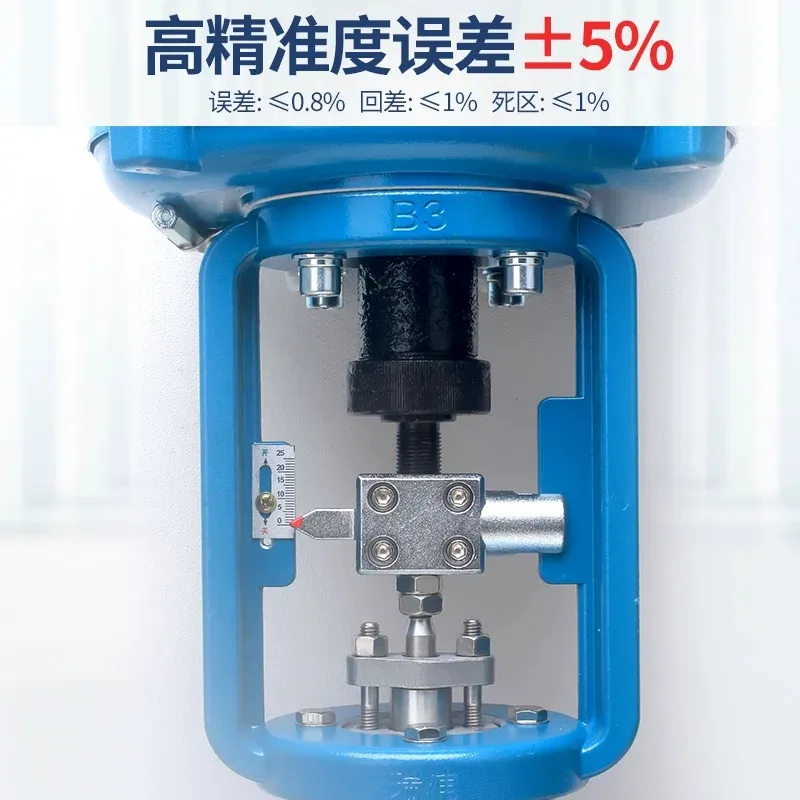

The valve is powered by the 3810L series linear electric actuator, which features a built-in electronic controller module. This integrated design accepts 4-20mA or 1-5V DC signals directly, eliminating the need for external servo amplifiers. It ensures high control precision, easy installation, and reliable modulation.

✅Balanced Trim for High Stability (Sleeve/Cage Design)

Utilizing a balanced valve core (Sleeve/Cage type), the valve effectively neutralizes unbalanced forces, allowing it to operate smoothly even under high pressure differential conditions. The large guiding area of the sleeve minimizes vibration caused by eddy currents and reduces mechanical wear.

✅Low Noise & Cavitation Control

Compared to standard single-seat valves, DELCO’s sleeve design optimizes the flow path to reduce operational noise by approximately 10dB. The cage structure also helps mitigate cavitation and flashing damage in high-velocity liquid applications, extending the valve's service life.

✅Versatile Flow Characteristics

The valve offers inherent Adjustable Ratios of 50:1, with flow characteristics available in Linear or Equal Percentage. This ensures accurate responsiveness across a wide range of process conditions, from fine throttling to full flow capacity.

✅Wide Temperature & Material Range

Standard bodies are cast in Carbon Steel (ZG230-450/WCB) or Stainless Steel (304/316). With varying bonnet designs, the valve operates reliably in temperatures ranging from -250°C (Cryogenic) to +450°C (High Temp), making it suitable for chemical, power, and steam applications.

Photo

Photo

Key Application Fields

-

Oil & Gas

DELCO API-certified valves ensuring safety and reliability in demanding high-pressure pipelines. -

Chemical & Petrochemical

DELCO corrosion-resistant solutions tailored for handling aggressive acids and hazardous fluids safely. -

Power Generation

DELCO solutions efficiently withstand extreme high-temperature and high-pressure steam cycles in power plants. -

Food & Pharmaceutical

DELCO sanitary valves with FDA-compliant, crevice-free designs to ensure absolute product purity. -

Water & Wastewater

Durable municipal solutions by DELCO, designed for zero leakage and long-term sustainability. -

HVAC & District Heating

DELCO valves ensure precise flow regulation to optimize energy efficiency in modern buildings.

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application